If you are a grower in the controlled environment agriculture (CEA) space, you probably know just how important a well-designed HVAC system is for your cultivation facility. There are countless articles on this topic, including our own guide for choosing the best grow room climate control system.

Unfortunately, getting the right system is still hard for a lot of growers. For many of them, knowledge of their HVAC system starts and ends with knowing a brand name. Of course, this spells disaster and the growers end up stuck with inadequate systems.

A key issue for most growers is that many of the HVAC system brands out there are not designed to work in CEA facilities. So here we are with another piece to elaborate on proper HVAC system selection. Combine this with the guide we highlighted above, and you’ll be in a better position to select a system that works well for your facility and helps increase your operation’s profitability.

What does proper HVAC system selection entail?

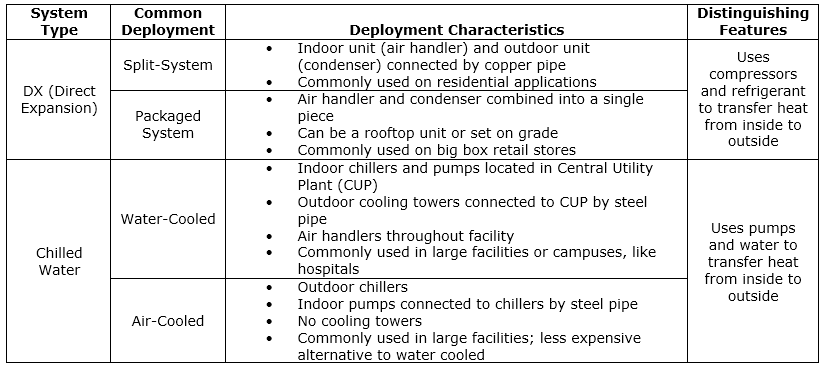

To truly know about your HVAC system, you first need to know the different types of systems out there (and no, we’re not talking about brand names here). While you can do any number of searches for a comprehensive list of HVAC system types, at their simplest, you can break down HVAC systems into two main types: direct expansion (DX) and chilled water.

A DX system uses refrigerant and compressors to transfer heat from the inside to the outside of a CEA space. On the other hand, a chilled water system uses water and pumps to transfer heat from the inside to the outside. Below is a summary of these two system types and the deployment variations that you may see for each.

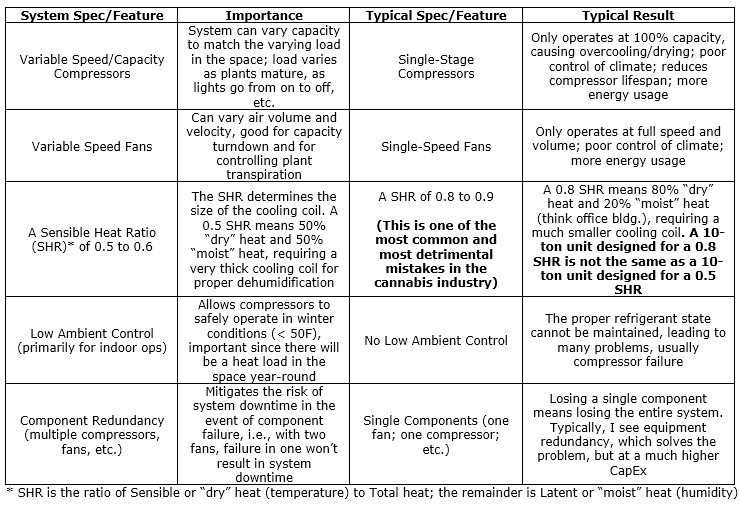

More important than the system type, you need to know the specifications and features of a system.

Why?

Because the features and specs will speak to the appropriateness of the system design for a given application. Often, when a grower has issues with a certain HVAC system brand, the problem is not with the system itself, but rather with the specs and features of that system.

Some of the most important features and specs you need to know when selecting an HVAC system are variable speed compressors and variable speed fans, component redundancy, low ambient control, and sensible heat ratio.

Below is a summary of these specs and features, each compared respectively to the specs and features that are typically deployed in conventional HVAC systems.

Related content: Understanding HVAC: Key HVAC terms.

HVAC system design and optimization

HVAC system type. Check.

Important HVAC specs and features. Check.

Once you have these two factors covered, you need to take a deep dive into your system design and you also need to determine how you can optimize and tailor the system to your facility.

Design the system right

Robust HVAC system design can help with:

- High yields and operation growth

- Efficient energy use

- Pest and pathogen prevention

- Avoiding building damage by eliminating or minimizing condensation on surfaces.

In the following points we elaborate multiple considerations for good HVAC design for CEA spaces:

1. Invest in reliable and efficient equipment

This might sound obvious, but you’d be surprised how many people miss HVAC efficiency because of unreliable hardware. Make sure that your HVAC equipment comes from a trusted manufacturer.

One tip to keep in mind when selecting equipment is to know how easy it is to maintain. Ideally, you should check how easy it is to obtain spare parts and how easy it is to fix the equipment in case of a breakdown.

2. Remember that lights play a major role in CEA spaces

The number of lights you need in your cultivation facility will help you decide on HVAC design. This is because lights produce heat and the HVAC system will need to take care of this heat.

3. Consider power availability

HVAC and dehumidification account for around 51% of total electricity consumption in cultivation facilities. When designing an HVAC system, it’s important to consider power availability.

- What voltage is available?

- What backup power options are available and what is their voltage?

- Do we have a budget for a new power source if the existing electrical capacity is insufficient? Will this new power source still integrate well into the HVAC system design?

Answering these questions will help you design a system that will integrate into your facility seamlessly.

Other factors to consider when it comes to HVAC design include odor control capabilities and budget. The design process includes a lot of elements, which makes it all the more challenging. But you can start on the right path by knowing the HVAC design challenges you’ll likely face and how to avoid them.

Know system optimization to get the most out of your system

When selecting an HVAC system, you should be ready to optimize it so it meets your cultivation facility’s unique needs and operates more efficiently. System optimization is also a great way to address any issues that you didn’t resolve – or those that came up after – during design and construction.

Energy consumption is one of the key areas you can optimize to get the most out of your HVAC system. Items like high-efficiency compressors and ECM motors are easy places to start, but they do have a small impact on systems that run 24/7. Much like in the commercial world, CEA facilities need to look towards economization to try and remove as much mechanical cooling and dehumidification as possible, thus saving energy.

Economization and energy savings

The concept of economization is familiar in commercial HVAC design. Not only does bringing in outside air dilute the toxins and contaminants being produced in a commercial building, but on suitable days the outside air can even be used to condition the space itself. However, with CEA facilities growers move the crop inside to try to limit exposure to the pests and pathogens commonly found outside, and to keep CO2 levels high. Thus, traditional outside air economization works against the fundamental goals of a CEA facility, putting the predictability of the product at risk.

As a result, growers need to consider alternative economization methods.

To maintain the integrity of the environment, indirect economization is the best approach. Indirect economization uses outside air to indirectly cool a space when the outside air conditions are within specified set points. A heat exchanger does the economizing in the system – it isolates the impact of outside humidity and prevents outdoor air pollutants from entering the cultivation space.

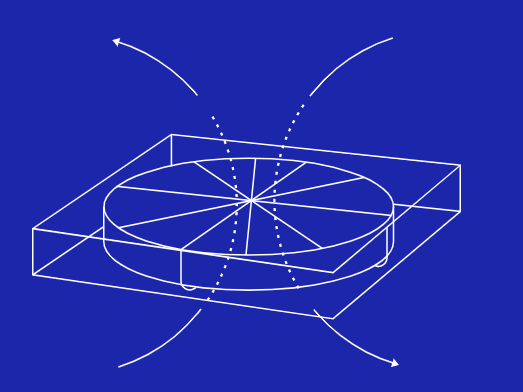

In CEA spaces, a recirculated air stream (in this case from the growing environment) flows across one side of the heat exchanger and the other side using the outside air as a heat sink; running the air across the heat exchanger and exhausting it back into the atmosphere. Heat is transferred from the recirculated air stream into the heat exchanger and then passed on to the outside air.

This approach is common and well understood when transferring sensible heat. However, the latent heat of cultivation spaces further complicates indirect economization, thus limiting available options. Although a lot of growers are familiar with heat pipes, run-around coils, or fixed-plate heat exchangers, the application of these products transfers sensible heat but allows the latent heat in the space to build. The answer for indirect economization of a CEA facility is a heat exchanger that can transfer both sensible and latent heat.

Two main types of energy recovery devices accomplish this: total energy wheels and enthalpy cores. Both are commonly used in commercial buildings for:

- recovering energy from relief air before being exhausted; and

- transferring that energy to the outside air being brought into the space.

When used as an indirect economizer, the energy recovery device sits between the return air and outside air streams. On one side of the device, return air is recirculated to the space, and on the other, outside air is pulled through and exhausted.

The aluminum frame of the total energy wheel or enthalpy core absorbs and releases sensible heat. Latent heat is transferred at a molecular level, as water vapor, and only occurs on the surface of the wheel. The vapor pressure difference between the opposing air streams is what drives the water vapor transfer. In the end, all the moisture transfer happens without the energy-intensive process of mechanically cooling the air down to dewpoint. This means that growers can achieve dehumidification indirectly with simple fans and either a total energy wheel or an enthalpy core.

The effectiveness of the heat exchanger maximizes the number of hours throughout the year capable of indirect economization. Depending on your location, you can expect to turn your compressors OFF up to 40% of the year.

Conclusion

CEA is here to stay and robust HVAC systems are a must-have. “Off the shelf” systems are no match for the complex CEA spaces, and only application-specific, application-appropriate systems will give you the performance you need in your growing space. Getting such a system requires going through the proper HVAC system selection process.

And once you have chosen the best system for your facility, make sure to avoid these three common mistakes that can cost you HVAC performance.