HVAC systems are energy-intensive. They are generally responsible for a significant proportion of a cultivation facility’s energy consumption. This makes sense if you consider how an element such as latent heat is very difficult and energy-intensive to remove from a space.

However, as sustainability takes center stage and the need for sustainable cultivation practices intensifies, high energy consumption is now an issue that requires urgent addressing. One of the critical factors that need addressing is the use of brute force to cool and dehumidify.

HVAC systems and brute force

Brute force is an approach used to control humidity. When using brute force, the air in a cultivation space is overcooled to reduce humidity then it’s reheated to achieve the desired temperature. Seems counterproductive, right?

This goes to show why the use of brute force is not such a great idea. Not to speak of how costly brute force is, or the fact that the whole reheat/overcool process is generally disallowed by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) standard 90.1-2010.

To overcome the problem, some leaders in the HVAC space have been researching ways to eliminate the use of brute force and make HVAC more energy efficient. The Harvest Air wheel is one such tool being used to eliminate the use of brute force.

The Harvest Air wheel

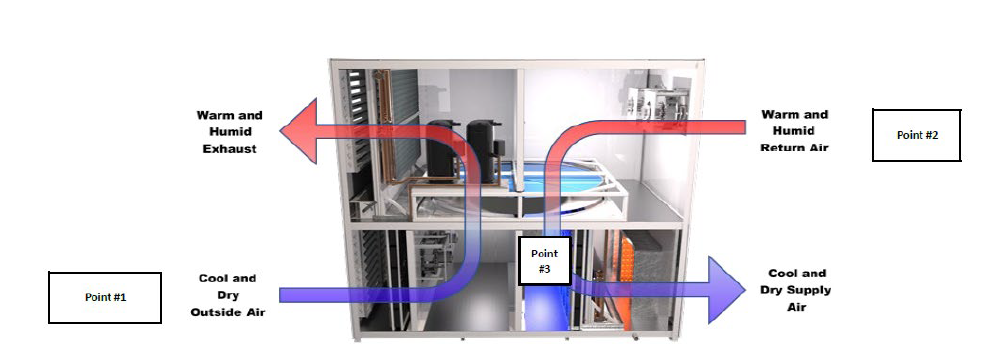

The Harvest wheel is a rotary heat exchanger used for indirect air-to-air economization. In the industry, the wheel is known as an enthalpy or total energy wheel. The use of the name “Total Energy wheel” stems from the fact that as two different air streams pass through the wheel, both heat and humidity (i.e., the total energy in the air) are transferred.

The idea of heat/temperature transfer is easy to understand for most people. Since heat will always move from a higher temperature object to a lower temperature object, this is something we can feel, like the heat from a fire or the warmth of the sun. The wheel rotates through the separate air streams transferring the heat from one air stream to the cooler air stream.

Humidity transfer is very similar, but we can’t feel it or see it. As two different air streams pass through the wheel, moisture is absorbed and released, respectively. Much like heat transfers from high temperatures to low temperatures, the same is true of humidity, only it transfers from high humidity to lower humidity. So as the wheel rotates through the separate air streams it transfers moisture (humidity) from higher humid air to dryer air.

Are you familiar with the little silica gel packets often found in shoeboxes? Those packets placed in packaging for products that are susceptible to moisture, as a way to keep them dry during transit? That same silica coats the Harvest Air Wheel, removing moisture from areas of high humidity.

Using the Harvest Air wheel means the Harvest Air™ HVAC system doesn’t rely on brute force and mass energy to cool and dehumidify a cultivation space.

The best part?

The wheel is 85% efficient, allowing compressors to stay off as much as possible. When you consider that the most efficient compressor is one that’s not running, you can see just how great the wheel’s high efficiency is.

Wheel performance example

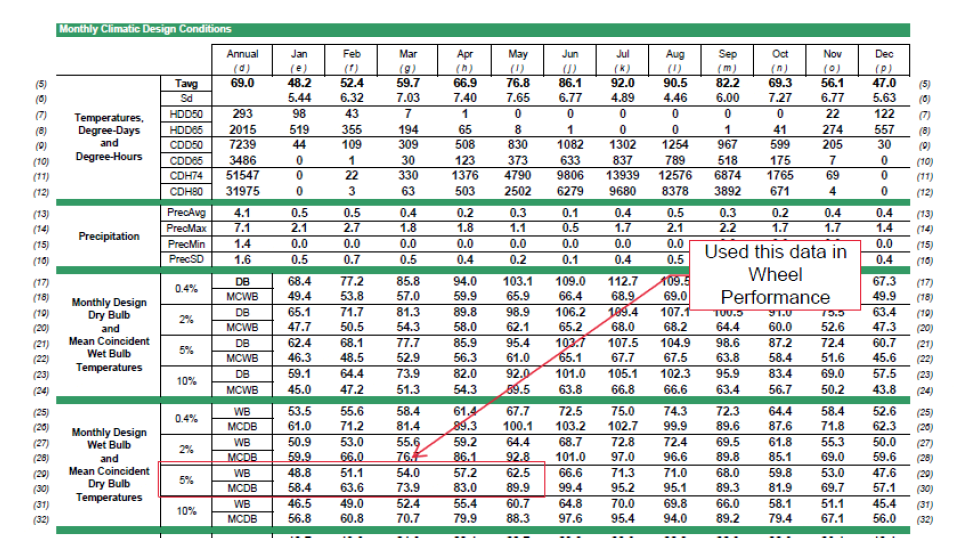

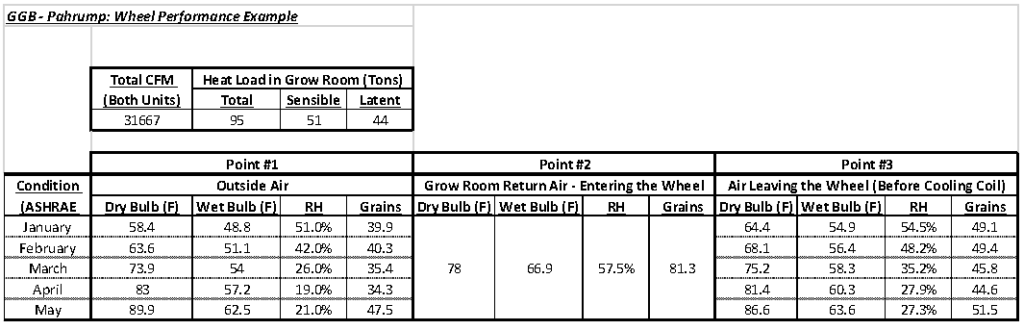

The following wheel performance example takes ASHRAE weather data, seen below, from Pahrump, NV for 5 different months. (January, February, March, April, and May).

The temperature (i.e., “dry bulb temperature”) and resulting wet bulb temperature (a measure of humidity in the air) listed in the table represent ambient conditions that are appropriate to design to.

You can see where we loaded those numbers in the spreadsheet at point #1. Point #1 is the outside air that we will use as a heat and humidity “sink”. In other words, if the heat in the outside air is lower than the heat in the grow space return air, noted as Point #2, then the wheel will transfer the heat from the grow space to the outside air.

Conversely, if the humidity in the outside air is lower than the grow space return air, then the wheel will transfer the humidity from the grow space to the outside air. We noted the resulting condition of the air, after the wheel has performed the heat and humidity transfer, at Point #3. To be clear, Point #3 is after the wheel and before the DX coil, so the DX system (i.e., compressors) will do any further conditioning of the air.

January

Let’s walk through the January example.

A Harvest Air Wheel selection was made representing “January,” as noted in the wheel performance example spreadsheet. Let’s start with the heat. As discussed above heat will transfer from higher temperatures to lower temperatures.

For January, the outside air, or “heat-sink,” is 58.4 degrees, compared to 78 degrees in the grow space return air. As a result of the heat transfer through the wheel, the supply air temperature off the wheel is 64.4 degrees. In other words, the 58.4-degree wheel was able to remove 13.6 degrees (78 – 64.4) from the grow space air.

More important is the humidity. Relative humidity by definition is a relative metric, so it changes as the temperature of the air changes. In HVAC design, a more accurate metric is absolute humidity, which is a direct measure of the amount of moisture in the air. Absolute humidity is defined as the “grains of moisture per pound of dry air,” or gr/lb.

As highlighted before, humidity will transfer from higher humidity to lower humidity. For January, the outside air, or “humidity-sink,” is 39.9gr/lb of moisture versus 81.3gr/lb of moisture in the grow space return air stream. As a result of the humidity (moisture) absorbed through the wheel, the supply air humidity off the wheel is 49.1gr/lb of moisture. In other words, the 39.9gr/lb of moisture of the wheel was able to remove 32.2gr/lb of moisture (81.3-49.1) from the grow space air. For context, we expect a reduction of 28 – 30 grains when designing HVAC systems and sizing Harvest Air units for grow rooms.

You can follow the other examples as they relate to other months, but in the end, why is this a big deal?

Currently, the only way to remove humidity from grow room air is by condensing it out of the air, similar to a glass of iced tea. You have to cool the temperature of the air down to below its dewpoint before you can remove the humidity, or in the case of the glass of tea, before water droplets form on the glass. Mechanical refrigeration is the only way to accomplish this, and whether that comes in the form of a direct expansion (DX) or chilled water system, compressor energy still has to be spent to drive the temperature of the air down to the dewpoint.

Furthermore, by using mechanical refrigeration, you can remove the humidity, but consequently, the air is too cold to directly supply to the space; often near 50 degrees. This forces a “re-heat” scenario where you’ll require even more energy to re-heat the air before it is delivered to the space.

Although Harvest Air units still use DX cooling, using the wheel as the primary source of cooling and dehumidification allows growers to effectively turn their compressors off 50%+ of the year, saving energy and improving their bottom line.

Looking to switch to a more efficient HVAC system and create a more sustainable indoor cultivation space or greenhouse? Contact us today!