Grow room automation is transforming indoor cultivation operations. From automating lights and fans to collecting important data, automation is helping improve and optimize plant quality, grow room environmental control, operation efficiency, and other variables.

As a result of these many benefits, grow room automation is also promoting what has become one of the critical factors in any grow operation – sustainability.

So grow room automation is changing the indoor grow landscape, but what exactly do we mean when we refer to grow room automation?

What is grow room automation and why is it important?

Although the term automation tends to conjure images of assembly lines with machines and robots, things are not always that complex. Put simply, automation refers to the introduction of an automatic system or technology in a process or facility, i.e. the system or technology ensures that tasks are completed with little to no human assistance.

Based on this definition, grow room automation is essentially the introduction of technology or systems that centralize the control of a grow room. Since each grow room is unique, grow room automation comes in all shapes and sizes. Some growers are tech-savvy and prefer high-tech automation solutions while others are more hands-on and prefer to take care of much of the grow room control themselves.

Ultimately, some form of grow room automation can improve a grow operation whether a grower is very progressive or more conservative and traditional.

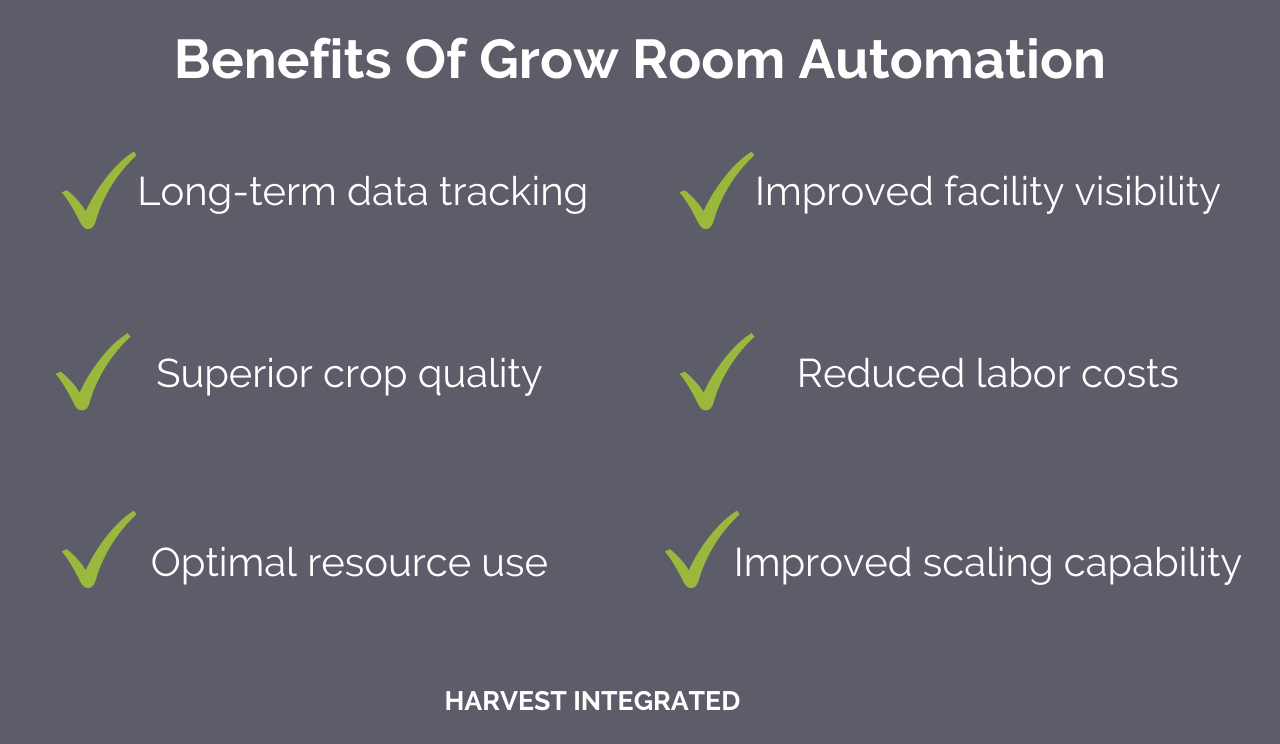

Here are some top benefits of automating a grow room:

Superior crop quality

One common way of introducing automation to the grow room is through centralizing equipment such as lights, irrigation systems, fans, humidifiers and dehumidifiers. With this type of automation, controls and sensors are programmed to respond to any changes in the growing environment.

The required grow environment parameters are very specific and the controls pick up and alert the grower to any drift from the optimal range. Automation helps create an optimal growing environment that protects crop quality and yields – two critical elements for grow operation success and profitability.

Read more about the different controllers you can use to automate a grow room in The Ultimate Guide to Grow Room Controllers.

Improved facility visibility

Fully integrated automation allows for data collecting, giving visibility into what’s going on throughout the entire grow facility. Growers can see how the crop is doing as well as how the equipment and other mechanical systems are operating.

Having access to a wealth of data at any given point means growers don’t always have to spend time assessing every part of the operation. In most cases, they need only assess the things that are not working, thus freeing up more time to focus on the crop.

Long-term data tracking

An automated system allows growers to track data over time. As growers collect more data they can determine the optimal conditions for the best crop quality and optimal efficiency. Once growers have collected enough data they can program their “recipe for success” into the system so that it’s executed and repeated effortlessly.

Reduced labor costs

When an industry grows, the way the indoor grow industry is, profit margins tend to get thinner. Automation reduces the time and labor that goes into performing duties in a grow room, thus reducing costs and preserving margins.

Instead of relying on workers to constantly walk around and manually monitor things such as the watering of plants, thermostat settings, CO2 levels, and lights, all these functions can be automated.

An automated system eliminates the need for constant human checking and gives growers remote access to monitor and control growing conditions. In many cases, growers can control their facilities from just one point. This reduces the overall workforce demands and allows for a consistency that may not always be easy for humans to achieve.

Optimal resource use

When growers do everything manually, it’s easy to waste resources. Do the lights or fans keep running when they are not supposed to? Is there someone to constantly monitor that all the required parameters are staying within the required ranges?

With automation, growers can adjust the grow lights to varying intensities depending on the growth stage and plant requirements, and the lights are automatically turned on and off at certain times. Humidity and temperature are also adjusted automatically to suit the plants’ needs at each growth stage. Resources are only used when necessary and if levels fall outside set parameters, the system notifies the grower.

These are just two, albeit good examples of how automation ensures optimal resource usage. By optimizing how equipment and mechanical systems run, automation lowers costs further (think about the lower utility bills, for instance).

Improved scaling capability

As an operation scales, it becomes more difficult to run and monitor it. Having an automated system makes it easier to manage an operation, even when it’s getting large.

All these automation benefits help make grow rooms more sustainable. Let’s look at the how part.

How does grow room automation promote sustainability?

An important element of a grow room’s sustainability is its environmental sustainability.

One of the biggest issues when it comes to grow room sustainability is high energy consumption, particularly the consumption connected to grow lights and HVAC systems. Automation helps address this issue.

For example, by automating grow lights, cultivators can dramatically reduce energy demand. Instead of guessing the required amount of lighting at any given time, cultivators can make decisions based on real-time data for increased efficiency.

Energy is a huge contributor to greenhouse gas emissions. Therefore, the increased energy efficiency brought about by automation will play a significant role in promoting sustainability.

Besides lights, grow room automation also helps optimize the use of other resources such as water. For example, cannabis, one of the crops popularly grown in grow rooms, is water-intensive. With automation, growers can ensure that the plants get only the water they need, not more. Efficient water management is a must, especially now with the worsening climate change and droughts.

Related Reading: Want to learn more about cannabis grow room sustainability and how you can make your own grow more sustainable? Read “How to Create A Sustainable Cannabis Grow Facility”.

Automation increases an operation’s sustainability as well. A big contributing factor to this sustainability is the reduction in operating costs. When you operate in an industry where profitability relies on maximizing efficiency, cutting costs is mandatory for business sustainability.

Reduced operating costs

We already looked at how automation reduces labor and utility bill costs, but there are more cost-saving opportunities for growers.

Growers can use data to catch problems that would otherwise go undetected. If a grower is monitoring data regularly, they will notice deviations that may signal a problem with the equipment. Without the data, noticing a problem may take too long and result in costly equipment and system repairs.

Grow room automation also enhances a facility’s preventative maintenance scheduling. Instead of unexpected maintenance, automation allows for scheduled downtime. For example, if a system has to run for 40,000 hours before maintenance or replacing, a grower can set a reminder for when the system is about to reach this threshold.

This is much better than experiencing a breakdown and disrupting operations. With automation, growers can be proactive about system maintenance and optimization. This not only saves money but is key to achieving more sustainable practices.

Grow room automation for the win

The need for sustainability is becoming more crucial as we grapple with climate change issues and an increasingly competitive industry. Grow room automation is certainly not a complete solution on its own, but it is one of the best ways for growers to achieve this sustainability.

If there is one thing to take away from all of this, it’s that grow room automation can make your facility better. How much of your grow room you want to automate will depend on your needs, but there are definitely immense benefits there, improved sustainability included.