Running any business is hard. Keeping up with industry regulations, finding and retaining competent staff, providing great service, getting funding, and managing costs are just a few of the obstacles you have to navigate to set up a successful business. Running a cannabis grow operation is harder — all these problems are magnified exponentially. Scaling said operation, however, is in a league of its own. It’s fraught with even more challenges and hurdles.

Put simply, scaling a cannabis cultivation operation is a high-stakes undertaking. But just because it’s hard doesn’t mean it can’t be done. You just need to be tactical; taking the time to understand what scaling cannabis cultivation entails and the challenges you may encounter. With that said, here are nine key grow op scaling problems you will likely encounter and some possible solutions.

1. Maintaining product quality

A grow operation is only as good as the quality of its product. Still, producing a constant product remains one of the biggest challenges in cannabis cultivation, especially when it comes to medical cannabis. Even more challenging is trying to maintain product quality while also focusing on the growth of the operation. As a result, it’s not uncommon for product quality to suffer as management focuses on growth. This shift in focus will, however, generally hinder scaling efforts since it will be hard, if not impossible, to achieve growth without a good product.

It’s important not to compromise on product quality and one way to ensure that quality remains consistent as you scale is to have clear, accurate and concise cultivation standard operating procedures (SOPs). Cultivation SOPs are documents that outline your workflow and processes to help ensure that processes are undertaken the same way each time. This limits any variables that may produce unexpected outcomes, essentially bringing consistency and structure to your operation. For example, if you have robust SOPs and your team is familiar with them, it will be easier to pick up any environmental control metric that falls outside a specified range.

Identifying all the processes you want to standardize and producing cultivation SOPs can be labor- and time-intensive — each stage of the grow cycle involves different processes, resources and metrics. Nonetheless, the quality management and product consistency you can get from using SOPs are worthwhile. If you’re unsure where to begin, this SOP bundle can help you create some SOPs or improve on any existing documentation.

2. Legal and regulatory pressures

Basement grow days were simpler. They were characterized by few market pressures and no worries about government regulations. Things are different now and growers are faced with many legal and regulatory issues. The bigger an operation, the bigger a target it is for rigorous yet often unclear regulations that tend to change frequently. There’s also the pending issue of legality at the federal level. Consequently, growers can’t make any long-term decisions based on current laws, plus finding reliable counsel in the cannabis legislation space isn’t always easy. This puts grow operations at risk and scaling is difficult, particularly if it involves entering into new jurisdictions.

One of the best solutions to this problem is evaluating the regulatory landscape according to your needs. You can’t adopt a one-size-fits-all approach to legal and regulatory issues. This means that if your scaling plans involve entering a new location, you analyze the regulatory environment in that specific location. It’s also prudent to keep up with looming developments such as the federal legalization of cannabis. Moreover, having an experienced attorney to help you navigate the ever-evolving regulations is not a bad idea.

3. Financing problems

Lack of access to traditional financing is one of the primary grow op scaling problems. The banking and lending industry has restrictions when it comes to funding businesses operating in the cannabis sector.

Private funding remains the best way to fund a grow operation, but, it usually doesn’t come easy. As such, it’s essential to have a sound business model that attracts investors, especially those who are risk-averse and need to see profitability before they commit their money to your operation. A good business model will also open up other potential financing avenues such as synergies and mergers.

4. People and culture issues

Although having the right team is important in every business, it’s even more important in cannabis production. Without a skilled and well-trained team to grow, process, and otherwise handle cannabis, your product quality will suffer and your scaling initiative won’t take off. But finding such a team is no easy feat since the rapidly advancing cannabis sector requires a diversified talent pool.

You will need to strategize your team structure right from the start. For instance, you will need to balance your grow room team with experts in areas such as technology and finance. Working with a recruiter dedicated to the cannabis sector can make choosing the right people easier since you’ll likely get people with very specific skillsets and experience.

In addition to having the right people, having the right people who are culturally aligned with your company is also important. Good company culture makes it easier to build goodwill, which allows for easier scaling while remaining competitive in the sector. Some great ways to cultivate company culture include recognizing and appreciating hard work, ensuring safe working conditions, promoting workplace ethics, and prioritizing timely and constructive feedback. Once you have the right team that’s propelled by great company culture, you’ll be in a good position to scale.

5. Knowledge gaps that affect scaling capabilities

The cannabis sector is riddled with knowledge gaps when it comes to scaling grow operations. Basement grow-ops were the norm for a long time such that commercial grow operations are a novel idea that still requires much exploration. Although the sector has evolved a lot in the last couple of years, the ideas and successes that applied to basement grows are proving difficult to apply to commercial grow op scaling.

Furthermore, the knowledge inconsistencies extend beyond the grow room and affect third parties such as equipment suppliers. Some solutions on the market just cannot address grow room challenges, let alone the scaling of cannabis cultivation. To avoid investing in facilities that won’t deliver value, it’s important to work with consultants and manufacturers who know the sector and offer products that are specifically built for cannabis growing.

6. Lack of standards

Standards bring consistency; they make it easier to apply the right solutions and handle unfamiliar environments. To date, the cannabis sector has no standards in place regarding buildings and systems. This makes the design process that much harder and engineers often have to improvise and borrow best practices from other industries and environments.

The drawback of this approach is that any improvisation and guesswork that fail to accommodate for the intricate processes involved in controlled environment agriculture, and cannabis, in particular, can result in costly mistakes. To avoid any unnecessary risk that hampers your scaling efforts with the lack of standards, it’s best to work with experts who are familiar with grow room environments and have proven experience in the field. That way, you can invest in your commercial grow op scaling with more confidence.

7. Using an HVAC system that’s not scalable

Getting the right HVAC system is a big deal in cannabis production. It will save you a lot of hassle in the long term, especially as you scale.

There are many approaches to HVAC that can be applied in the grow space, but not every solution will provide the best results. For instance, standard commercial HVAC systems may be relatively cheap and easy to set up, but they may not be well-suited to grow rooms. They will likely not be flexible enough to provide value in the grow room as you scale your operation. A standard system will have technical limitations that make it difficult to optimize various elements such as energy efficiency and crucial environment control factors.

For example, supplemental dehumidifiers can eliminate moisture, however, they typically have no air conditioning or outdoor heat rejection capacity. Any heat produced by the compressor goes back into the facility space, adding to the sensible heat and requiring more air conditioning. The result — reduced efficiency. As you scale, installing many separate low-capacity dehumidification units and pairing them with traditional air conditioning units will likely present a big installation and maintenance headache that results in an underperforming operation, and in no way helps your scaling efforts.

The best solution to this challenge is investing in a scalable HVAC system that is flexible enough to scale with your grow operation. More importantly, the system must be purpose-built for grow rooms. Investing in such a system means you don’t have to worry about installing many unnecessary units in your grow space or keeping up with high maintenance costs.

8. Ignoring grow space optimization

Scaling and getting more grow space usually go together. Nevertheless, this is not necessarily the best idea, both in economic and efficiency terms. Setting up a new grow space requires a considerable capital investment and any unused space may result in inefficiencies that adversely impact your cultivation expenses.

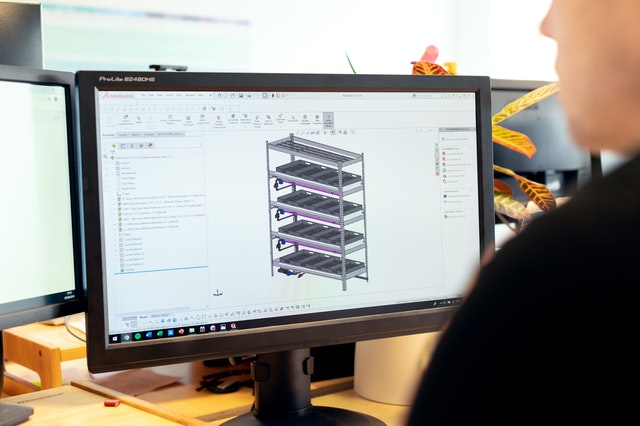

Instead of looking for more space, you may need to consider optimizing your current space. For example, you can look into vertical farming, which has been shown to double or even triple yield without any significant increase in expenditure. Using all the available space before moving to a new space will help make your scaling efforts more profitable.

9. Focusing on cultivation and ignoring marketing and branding

When it comes to scaling a grow operation, it’s easy to focus on scaling cannabis cultivation. Branding and marketing are put on the back burner because people are more concerned about the product, right? The fact of the matter is that running a grow operation is similar to running any other type of business, good branding and marketing are what shape public perception and relationships with customers whether you’re in the B2B or B2C space. As you scale, you will still need to maintain transparency, legitimacy and trust in your messaging.

Additionally, effective marketing and a strong brand identity will help you get your product in front of the customer and sustain your market presence in the hyper-competitive cannabis sector. Some things to consider when creating an expansion marketing and branding strategy include:

- reviewing all your outward messaging to communicate how your business operation is evolving as you scale

- ensuring consistent messaging to stay true to your brand even as you expand your operations

The bottom line: How to scale a cannabis cultivation operation

There’s generic scaling then there’s successful scaling. The latter starts with prioritizing a solid foundation, establishing a profitable business model, and mastering your current grow operation before thinking about expansion. Once you have a business model that works and a plan for addressing the common grow op scaling problems, scaling won’t be so daunting. When done right, strategic expansion will give you steady growth, more profitability and wider access to consumers in the market.