Innovation plays a critical role in making agriculture more competitive and even sustainable. Vertical grow rooms are one innovative agricultural practice that’s grown over the past several years. From cannabis to the leafy greens industry, growers are doubling down and reaping the benefits of vertical farming.

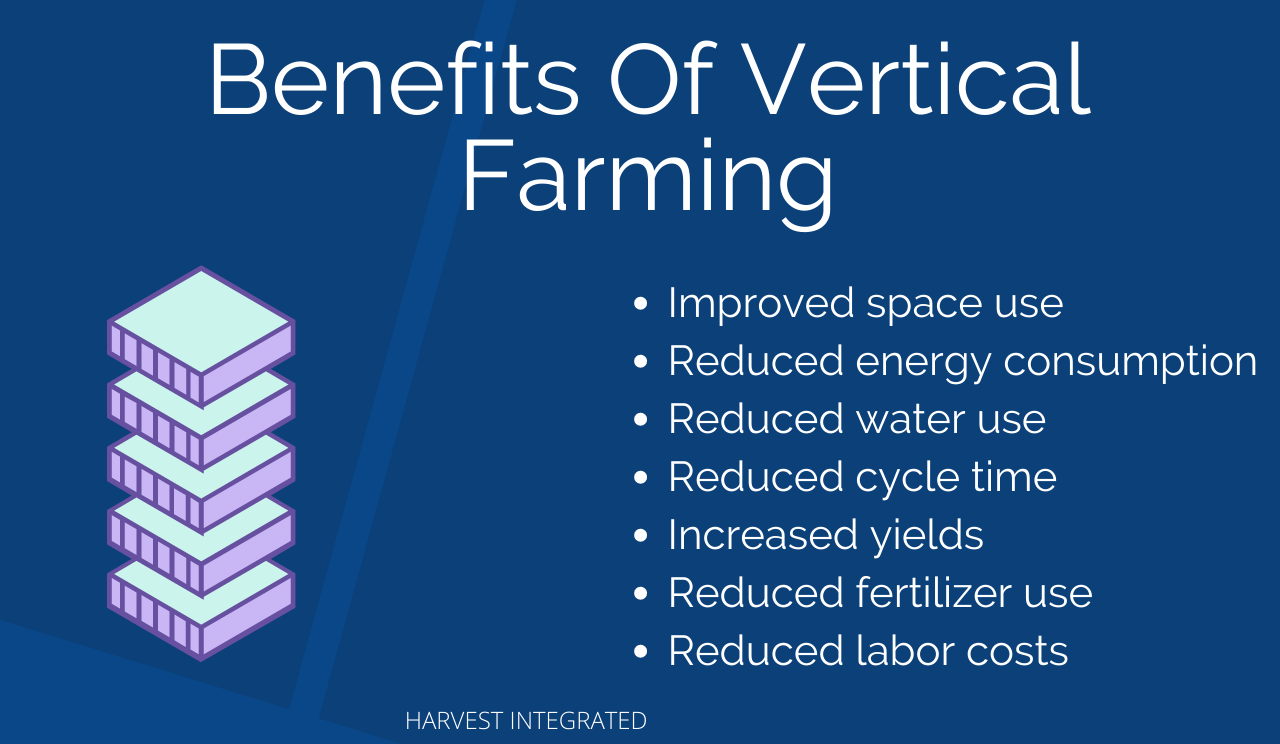

These benefits include:

- Better use of space

- Reduced energy consumption resulting in higher energy efficiency and reduced operational costs

- Reduced water use

- Reduced cycle time and increased yields

- Reduced fertilizer use

- Reduced labor costs

However, as many people in the vertical growing space know, advanced setups come with their own unique set of challenges.

For one, the cost of setting up a vertical grow can be expensive. The level of technology and equipment growers need to start a vertical farm is specialized, requiring substantial investment if you don’t want to sacrifice the quality of your crop. Finding people skilled in vertical farming techniques can also be hard since you need to build a team of people who know what works and what doesn’t.

So how do growers ensure that they get the most out of their vertical grow room setups?

It all starts with following some best practices and doing what’s right.

#1 Plan your vertical grow space layout

Vertical grow rooms are unlike conventional single-tier grow facilities – it’s not always easy or efficient to work on the upper tiers of a vertical grow.

Whereas everything is on the same level in a conventional grow, in a vertical grow you have to use ladders and even some scaffolding to access plants on the top racks. Therefore, you need to plan your space layout.

For example, you will need to plan for wider aisles to accommodate any infrastructure used to reach the plants in the grow. Grow room racks are one such type of infrastructure you’ll have to consider when planning your space layout.

Space for the racks

Not all racks are created equal.

Consider stationary racks. They work, but they can become an issue when aisles are not wide enough. Growers will have a hard time moving in the grow space, for example, to inspect plants. Rolling racks, on the other hand, will minimize the amount of aisle space you need, helping you maximize production.

A good idea when setting up your vertical grow room racks is to have enough space on either side of a rack to be able to move and work in the grow space. Having a good amount of space between racks will ensure that you can reach each plant, and it will be easier to clean the grow space.

Space for the plants

Depending on how big your grow room is, you will also need to decide how you will maximize your space. After all, the whole point of growing vertically is to get the most out of your grow.

A simple way to maximize the use of your space is to determine the height of your plants relative to the height of the grow room. For instance, you can increase the number of tiers in a vertical grow by using short plants.

Note: Shorter plants can also help growers cut the amount of time and resources required for under-canopy pruning.

#2 Environmental controls are a must

Maintaining the correct environmental conditions in any grow space is a difficult task, requiring lots of fine-tuning to achieve precision. Maintaining the optimal environmental conditions in a vertical grow room is even more tricky.

You have plants stacked on top of each other for maximum space use and there’s not a lot of space to move air. Using fans won’t work so well since they will limit the number of tiers you can have in the vertical grow room. Any random conventional HVAC will probably not work either as the vertical grow space requires precision.

There’s a lot to think about when it comes to controlling the environment in a vertical grow.

Think about microclimates

While microclimates exist even in traditional grow rooms, they are a bigger problem in vertical grows. The more plants there are in a grow space, the higher the chances of microclimates developing throughout the space.

There are several reasons why vertical grow rooms are more susceptible to microclimates, from the lack of air movement to the higher temperatures that are common at the top tiers of a vertical setup,

But climate uniformity is crucial in any grow space, vertical spaces included. Microclimates mean your heating, cooling and dehumidification system has to work extra hard, plus the chances of excessive environmental conditions (e.g. humidity) increasing the likelihood of pest or disease infestation are high.

It’s important to distribute air well at multiple points throughout the grow space to minimize or even eliminate the effects of microclimates. The rolling racks mentioned earlier are a good way to keep up with the microclimates in a grow space. Unlike stationary racks that make mobility difficult, rolling racks mean you can monitor every inch of your grow room, making it easier to discover and address microclimates quickly.

Among other things, eliminating microclimates will help improve crop quality, increase yields and reduce energy costs.

Think about pest management

You also want to consider early on what your pest management strategy will be. The risk of crop loss in a vertical grow room is high as microclimates are common and airflow is limited. For instance, the more limited airflow is in a vertical grow room, the higher the chances of excessive humidity and transpiration issues that make it easy for pests, pathogens and diseases to thrive.

Being proactive is the best pest and disease management method. Work to prevent pests and diseases from even developing in your grow room. Additionally, have systems in place to monitor the pest and disease pressures in your vertical grow so you can act on any problems fast.

Consider a specialized heating and cooling system to help you get your vertical grow room environmental conditions right. Your entire crop depends on how well you maintain said environmental conditions.

#3 Get the lighting right in your vertical grow room

It’s important to get the lighting right in a multi-level growing system right.

Why?

The intensity of light in the grow space can dramatically influence how well your plants develop. Consequently, it’s a good idea not to have too much space between the light and canopy to allow plants to grow to their full potential. Using close proximity lighting in a vertical grow room will help ensure that every plant gets the required light.

But not every type of lighting will give you what you require so everything should be well thought out.

For example, high-pressure sodium (HPS) lights will be hard to use in vertical grows since they produce a lot of heat. Put them too close to the plants and a number of things may go wrong

Due to the little air movement in grows with a vertical setup, the lights will increase the air temperature in the grow space and the plants’ transpiration rates. This will cause the plants to wilt, and in extreme cases, lead to the plants’ stunted growth.

LED lights are a great choice for vertical grows. They produce far less heat, therefore, you can place them closer to the plants without the risk of plant damage. The intensity of LED lighting combined with the right environmental controls can result in faster plant growth.

In fact, plants under LED lighting can produce two to three times more cannabis per watt of power than those grown under HPS lighting, all the while using less energy. So you improve your yields while increasing your energy efficiency and cutting operational costs.

Nonetheless, no matter the type of lighting you choose for your vertical grow, invest in lighting that’s built well. Trying to cut costs by cutting corners can be costly in the long run.

#4 Have a look at the vertical grow’s irrigation setup

You need to plan out your irrigation if you want to avoid drowning the lower tiers of your vertical grow. This is because irrigating multiple levels of plants can lead to a disproportionate runoff of water to lower tiers.

Overwatering is a big problem. Plants growing in too much water have a limited supply of oxygen that roots require to function properly. Yellowing leaves are usually a sign of overwatering followed by slow, stunted growth and plant death in the end.

To avoid this, it’s vital to ensure that all irrigation equipment is properly sized to balance the irrigation supply and ensure that each level of the grow gets an even distribution of water.

#5 Assess your equipment

The last thing you want is your equipment making it difficult to maximize space use in your vertical grow room.

Will the lighting fit into your racks?

Will the cooling system be able to ensure consistent airflow throughout the space, even with multiple tiers?

Will the irrigation system be able to support the entire grow without any overwatering and underwatering issues?

These are some of the questions that will help you assess your equipment.

Choosing your equipment carefully will help you achieve an optimal growing environment that works well for crop health, maximizes production, and minimizes any problems that could come up.

#6 Always check regulations

When setting up your vertical grow room, you want to check the regulations in your area to ensure that you’re adhering to the stipulated plant count limitations. It’s easy to define your plant capacity based on your grow room size and design, but remember that it’s equally important to consider regulations.

Transforming cultivation with vertical grow rooms

Vertical growing is revolutionizing how crops are grown. But it’s not for everyone.

Making a vertical grow successful takes a lot of skill and commitment. Fortunately, the best practices outlined here will give you a leg up when it comes to setting up your vertical grow room.

Considering other ways to grow your crop? Check out this guide to sealed greenhouses.

Happy growing!